Tekla for students, educators, and academic institutions

Access Tekla’s award-winning structural engineering, design, and construction software. Free for students and educators. Low-cost for accredited institutions.

Students

Access Tekla’s suite of academic solutions, develop your design and engineering skillset, stand out from the crowd and kickstart your professional career.

Learn more

Educators

Access Tekla’s suite of academic solutions and teach design and engineering more effectively than ever.

Learn more

Learn more about Tekla products

Tekla software and Trimble Connect for academic users

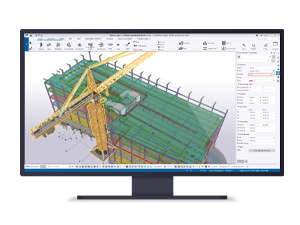

Tekla Structures

Structural design engineers, detailers, fabricators, contractors and project managers can create, combine, manage and share accurate models for every project. Work with any material, boost collaboration, enhance decision making and make your company famous for exceptional results.

Learn more

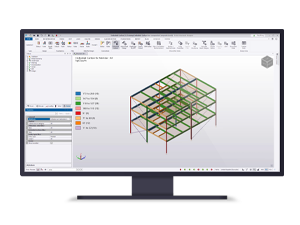

Tekla Structural Designer

Engineers can seamlessly combine design and analysis with just one robust, user-friendly single-model-based process. Build beyond limits, work with any material, and deliver safe, effective, and rationalized design faster than ever before.

Learn more

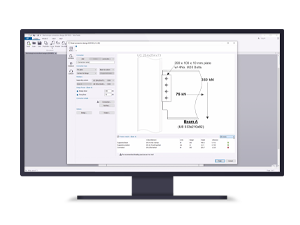

Tekla Tedds

Engineers can automate civil and structural calculations for speed, accuracy, and peak performance. Wave goodbye to tedium and hold projects in the palm of your hand. This powerful and easy-to-use analysis software gives you flexibility and freedom.

Learn more

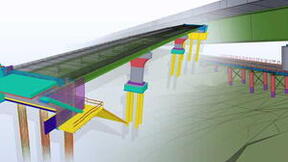

Trimble Connect

Everyone involved in your project can handle truly constructible data with Trimble Connect. Experience more with informed decision-making and keep your team members in sync. Seamless collaboration is the key to a successful project.

Learn moreLet’s get started

View our step-by-step process to ensure you get the best experience from Tekla Campus.

Tekla for education news

Tekla Global BIM Awards 2022 winners

Meet the world's 10 of the best structural designs and construction projects using building information modeling (BIM) around the world.

Read more

Modern and traditional live in harmony in an Indonesian student project

A student team from the Lambung Mangkurat University (ULM) in Banjarmasin, South Kalimantan, Indonesia, won the 2020 Tekla Global BIM Awards student category with the Kalimantan New Mosque project.

Read more

Trimble and WSU establish Trimble Technology Lab

Trimble (NASDAQ: TRMB) and Washington State University (WSU) have established a state-of-the-art Technology Lab in WSU's Voiland College of Engineering and Architecture. The lab serves the School of Design and Construction and the Department of Civil and Environmental Engineering.

Read more at TrimbleTrimble education and outreach

Learn more about Trimble's wider education and outreach programs across the globe